Continuous and overhead

shot blasting machine

with blast wheels

Continuous and overhead shot blasting machine with blast wheels

-

Client:AGRIO MZS s.r.o.

-

Year of implementation:2025

-

Location:Křemže (CZ)

-

Technical specifications:

- Max Product Dimensions:

L 8500 x H 2100 x W 1200 mm

- Max Product Weight: 2000 kg

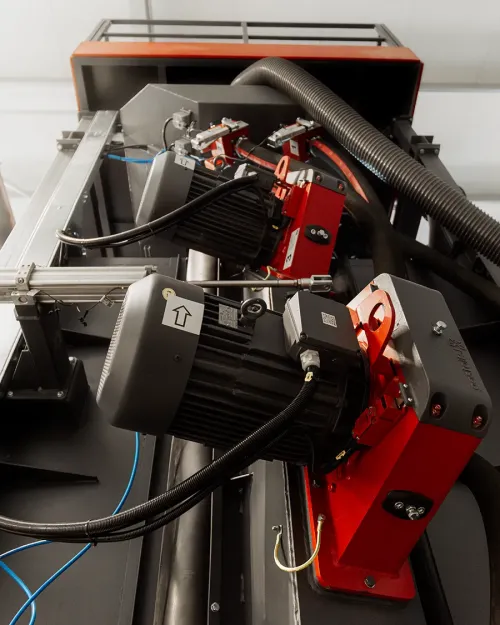

- 6× 11 kW blast turbines

- Max Product Dimensions:

-

Client:AGRIO MZS s.r.o.

-

Year of implementation:2025

-

Location:Křemže (CZ)

-

Technical specifications:

- Max Product Dimensions:

d. 8500 x v. 2100 x š. 1200 mm

- Max Product Weight: 2000 kg

- 6× 11 kW blast turbines

- Max Product Dimensions:

Technical Description of the Implementation

Automated Shot Blasting Machine Increases Production Efficiency for Field Sprayer Manufacturer

Agrio is a leading Czech manufacturer of field sprayers, with strong demand not only in Czechia but across Europe. Their new automated shot blasting machine optimizes the blasting of long metal parts, reduces operating costs, and increases overall efficiency. The installation of a tailored solution has significantly boosted Agrio’s production capacity. But where else in the workflow has this advanced industrial blasting system made an impact?

Robust. Efficient. Precise. These are the defining traits of Gostol TST blasting machines.

SURFIN Technology is an authorized representative of Gostol TST, one of the world’s leading manufacturers of blasting systems. Their machines are known for precise engineering and long-term operational efficiency. Wear parts are made from robust materials, significantly reducing replacement frequency and extending equipment lifespan. If you’re looking for a mechanical pre-treatment solution for metal surface preparation by blasting, Gostol TST is the right choice.

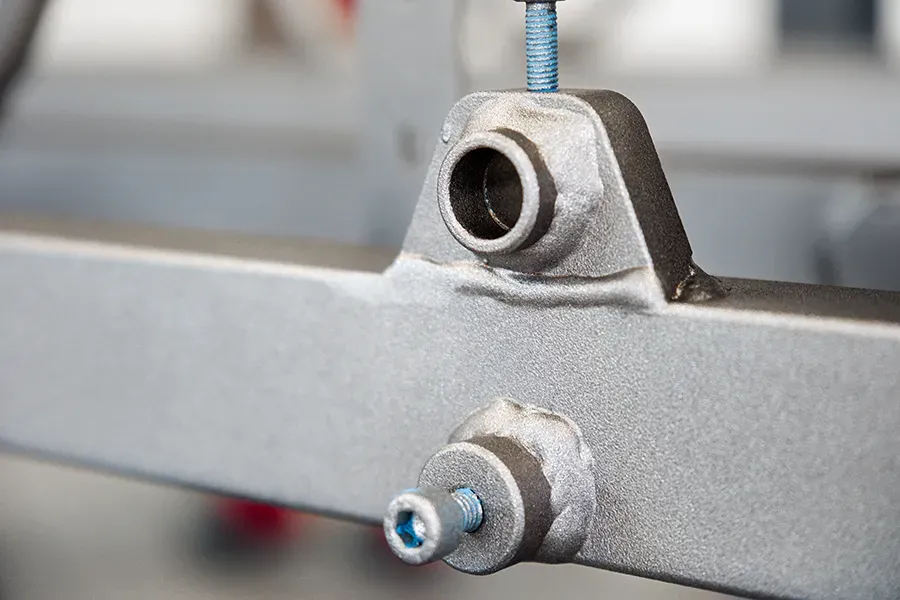

Blasting Wheels with Adjustable Blast Angle

The continuous blasting machine at Agrio was designed to easily and efficiently process parts up to 8.5 meters in length. Thanks to a clever system for adjusting the blast angle, multiple passes are no longer necessary — each part is fully blasted in a single cycle. This technology not only saves significant time in surface preparation but also reduces the floor space required for operation.

Blasting Machine with up to 2000 kg Load Capacity

To efficiently blast long parts and fully optimize the process, the machine features a loading station capable of processing multiple components simultaneously. With a load capacity of up to 2 tons, it’s possible to blast twice as many parts using the same amount of abrasive. This has resulted in lower rust and debris removal costs and significantly improved the efficiency of blasting large components.

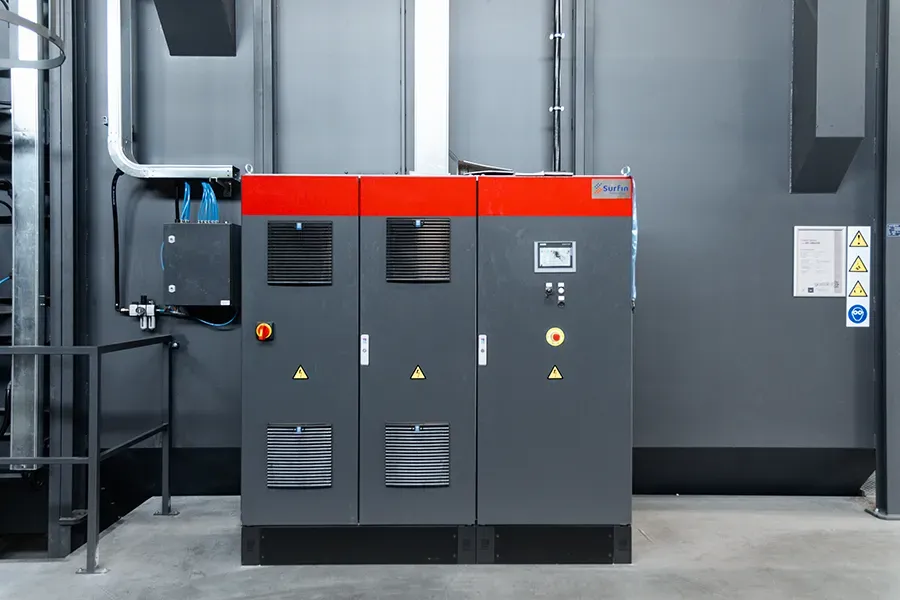

Intuitive Control via Touchscreen Interface

Setting up the blasting process has never been easier thanks to an intuitive control panel. Operators can configure all key parameters, create and store programs for different parts, and even adjust the blast angle with ease. The main screen displays essential data from the blasting turbines and immediately alerts the operator in case of any issues. The integrated panel simplifies the entire operation and enables seamless automation of the industrial blasting process.

Custom Blasting System Delivering Long-Term Value

The industrial blasting machine has enabled Agrio to significantly reduce the cost of metal surface cleaning. Process automation has increased overall efficiency and simplified machine operation, reducing labor time. The bespoke blasting system features a robust build and high-quality wear components, contributing to the long service life of the entire installation. By optimizing surface preparation, the system improves the efficiency of the entire sprayer production process.