Automated Powder Coating Line with Chemical

Pre-treatment

Automated Powder Coating Line with Chemical Pre-treatment

-

Client:Laser Kraft Steel s.r.o.

-

Year of implementation:2024

-

Location:Čerčany (CZ)

-

Technical specifications:

- Max Product Dimensions:

L 3000 x H 1500 x W 1000 mm

- Max Product Weight: 80 kg/m

- Conveyor speed: 0.5 m/min

- ESCO control system

- Five-stage spray pre-treatment

- Nebula passivation system

- Nordson Encore application technology

- Automatic coating booth

- Manual touch-up station with Nordson Encore LT

- Wastewater treatment unit with neutralization station

- Demineralized water station

- Drying oven

- Curing oven

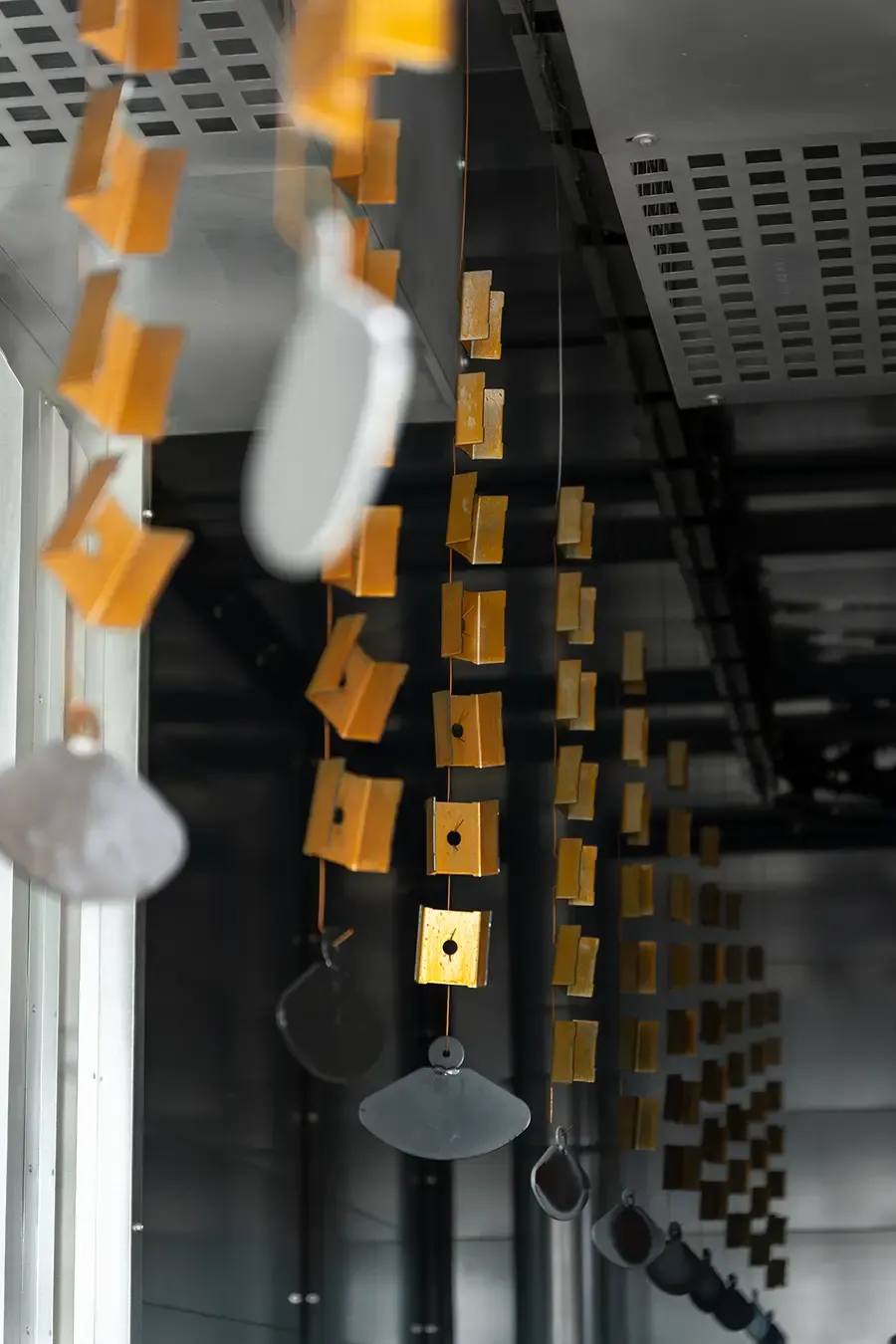

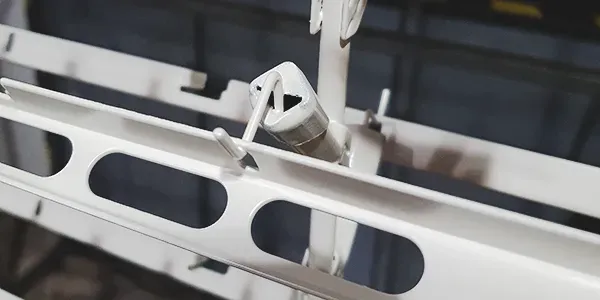

- Overhead continuous conveyor

- Max Product Dimensions:

-

Zákazník:Laser Kraft Steel s.r.o.

-

Rok realizace:2024

-

Lokalita:Čerčany (CZ)

-

Parametry technologie:

- Max. rozměr výrobku:

d. 3000 x v. 1500 x š. 1000 mm

- Max. váha výrobku: 80 kg/m

- Takt linky: 0.5 m/min

- Řídicí systém ESCO

- Pětistupňová postřiková předúprava

- Pasivační systém Nebula

- Aplikační technologie Nordson Encore

- Automatická lakovací kabina

- Ruční dostřikové pracoviště s Nordson Encore LT

- Čistička odpadních vod s neutralizační stanicí

- Demi stanice

- Sušicí pec

- Vytvrzovací pec

- Podvěsný kontinuální dopravník

- Max. rozměr výrobku:

Technical Description of the Implementation

Laser Kraft Steel Enters the World of Automated Powder Coating with Industry 4.0 Standards

For years, Laser Kraft Steel s.r.o.Laser Kraft Steel s.r.o. focused primarily on metal production and laser processing. Looking to expand their capabilities, they turned to us in search of the best powder coating technology to meet their needs. The result of our cooperation is a fully automated coating line with a five-stage chemical pre-treatment. Built to Industry 4.0 standards, the line not only enables complete series coating but also introduces smart production control and data collection through the integrated ESCO control system. This new automated coating solution is therefore an excellent choice for a newcomer to the surface finishing industry. What additional benefits does the line provide?

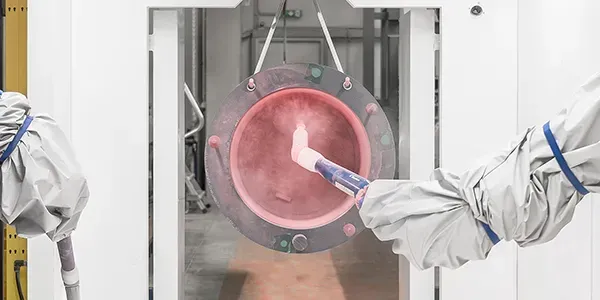

Chemical Pre-treatment with Passivation for Maximum Durability

A flawless powder coating finish starts with proper surface preparation. That’s why the line is equipped with a five-stage spray pre-treatment and a Nebula passivation system with misting frame. This combination ensures higher corrosion resistance and greater versatility – the company can handle both standard orders and projects requiring long-term durability. The line’s water management system is equipped with a wastewater treatment plant, a neutralisation station, and a demineralised water unit, guaranteeing consistent pre-treatment quality while remaining environmentally responsible.

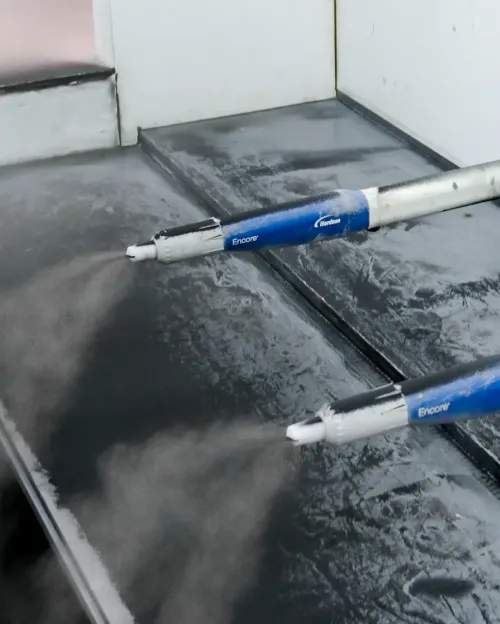

Automated Coating with Manual Touch-Up Capability

At the heart of the line is automated coating in a modern booth with Nordson Encore application technology. The automated process ensures consistent application of powder coatings, even on large production runs, and delivers high efficiency. For complex parts, the booth is complemented by a manual touch-up station with a Nordson Encore LT powder spray system. Thanks to this combination, customers can be confident every product receives a perfect finish – even in hard-to-reach areas.

Powder Recycling and Energy-Efficient Operation Thanks to ESCO

The line includes a powder recycling system, minimising powder consumption and reducing operating costs. Residual heat from the curing oven is used to heat the drying oven, saving additional energy. The entire line is controlled by the ESCO control system, which continuously monitors temperatures, processes, and water management, providing operators with all essential information in one place. If an issue is detected, the system immediately alerts the staff. These solutions make the new coating facility not only reliable but also economically sustainable and environmentally friendly – a modern powder coating technology fully aligned with Industry 4.0 principles.