Manual wet paint shop with smart ESCO control system

-

Client:EVPÚ a.s.

-

Year of Implementation:2025

-

Location:Dubnica nad Váhom (SK)

-

Technical specification:

- Internal dimensions of booths: L 6000 × W 5000 × H 4000 mm

- Internal dimensions of washing booth: L 6000 × W 4000 × H 3500 mm

- Dimensions of liquid coating preparation area: L 6500 × W 1700 × H 2800 mm

- Maximum drying temperature: 60 °C

- Combined coating / drying process booths

- Frequency inverter for regulating negative and positive pressure within the booths

- Plate air heat recovery unit

- Liquid coating preparation workstation including equipment

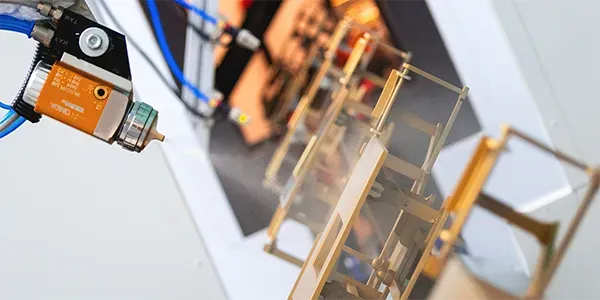

- Low-pressure and high-pressure GRACO application equipment

- Paint mixing station

- Automatic spray gun washer

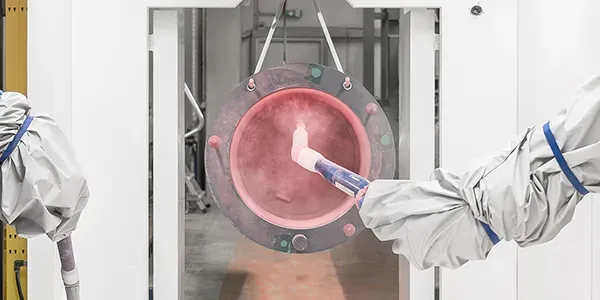

- Washing booth including water management system

- Diesel generator

- Wastewater treatment unit

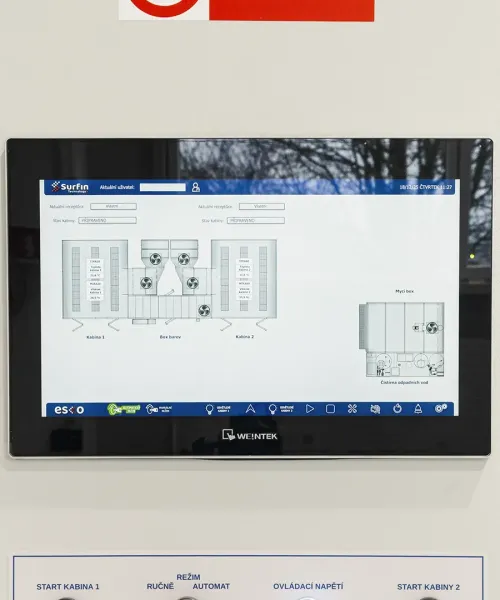

- ESCO control system

-

Client:EVPÚ a.s.

-

Year of Implementation:2025

-

Location:Dubnica nad Váhom (SK)

-

Technical specification:

- Internal dimensions of booths: L 6000 × W 5000 × H 4000 mm

- Internal dimensions of washing booth: L 6000 × W 4000 × H 3500 mm

- Dimensions of liquid coating preparation area: L 6500 × W 1700 × H 2800 mm

- Maximum drying temperature: 60 °C

- Combined coating / drying process booths

- Frequency inverter for regulating negative and positive pressure within the booths

- Plate air heat recovery unit

- Liquid coating preparation workstation including equipment

- Low-pressure and high-pressure GRACO application equipment

- Paint mixing station

- Automatic spray gun washer

- Washing booth including water management system

- Diesel generator

- Wastewater treatment unit

- ESCO control system

Technical Description of the Implementation

New Wet Coating Paint Shop Centralizes Surface Treatment

at EVPÚ a.s. in a Single Facility

New Wet Coating Paint Shop Centralizes Surface Treatment at EVPÚ a.s. in a Single Facility

EVPÚ, a manufacturer of sophisticated electronic solutions for transport, defense, and energy, approached us with the goal of creating an efficient technological solution that would combine pre-treatment, wet coating, and subsequent product dispatch within a single production facility. At the same time, the solution had to ensure consistently high output quality while maintaining a high level of flexibility for dozens of different products. The result is a comprehensive

wet coating technology featuring modern application equipment, smart control via the ESCO control system, and a strong focus on simplifying the entire surface treatment process.

Coating and Drying Without Capacity Constraints

The paint shop includes a manual washing booth, a liquid coating preparation area, coating and drying booths, as well as an intelligent control system. This allows the company to carry out the entire process in-house, without the need for external subcontracting. The wet coating technology is equipped with two combined process booths designed for coating, controlled evaporation, and drying. Parallel operation of both booths makes it possible for coating to take place in one booth while the other is used for evaporation or drying. This significantly improves production flow and eliminates process downtime. As a result, production capacity remains stable even with a variable product mix and differing process requirements.

Simple and User-Friendly Process Control with ESCO

A key component of the entire technology is the

smart ESCO control system, which supervises all critical process parameters. The system simplifies production by enabling recipe settings based on product type and coating material, controlling evaporation as well as drying times and temperatures, while continuously monitoring and reporting production data. Operators have clear, real-time information on booth operation, filtration load, and the current status of individual technological units. The solution also includes ESCO Aqua, which ensures monitoring and management of the paint shop’s water systems. Integration of the control system contributes to higher operational reliability, easier operation, and improved control over surface treatment quality.

More Energy-Efficient Heating of the Technology

The coating booths are equipped with a plate air heat recovery unit that reduces the paint shop’s energy consumption during the winter months. The recuperator uses waste heat from the extracted air to preheat the incoming supply air. This results in a significant reduction in heating costs and enables more energy-efficient and environmentally friendly operation of the technology.