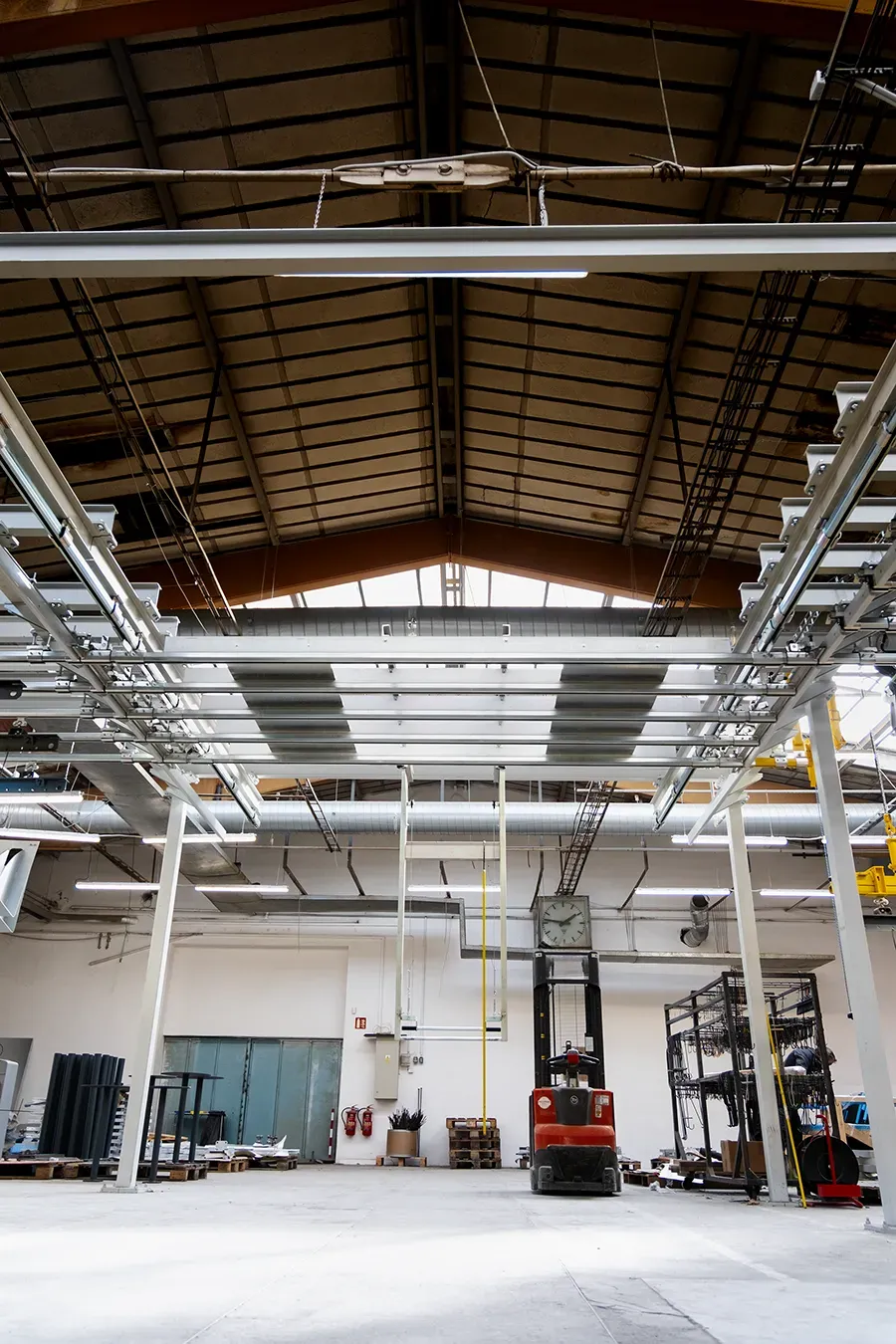

Manual Powder Coating Line for Urban Furniture Manufacturer

-

Client:mmcité, a.s.

-

Year of Implementation:2024

-

Location:Veselí nad Moravou (CZ)

-

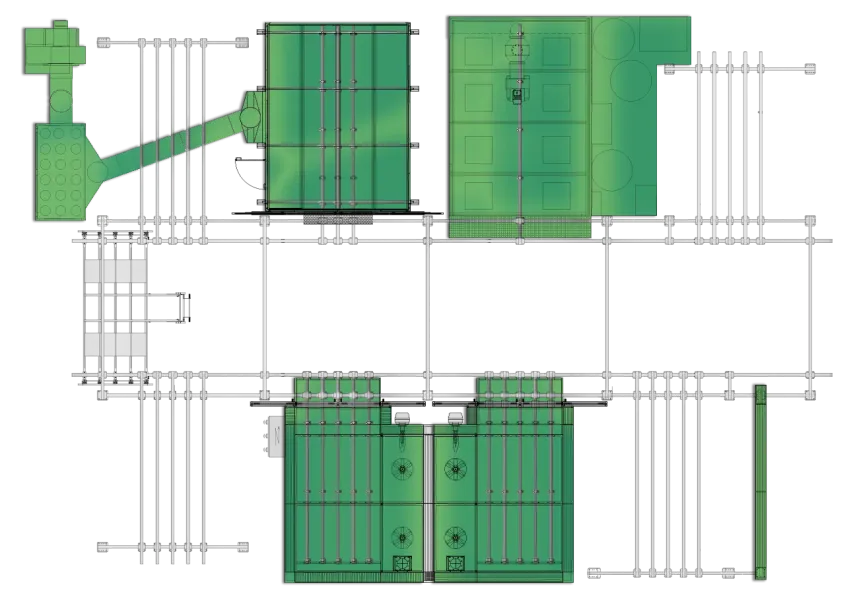

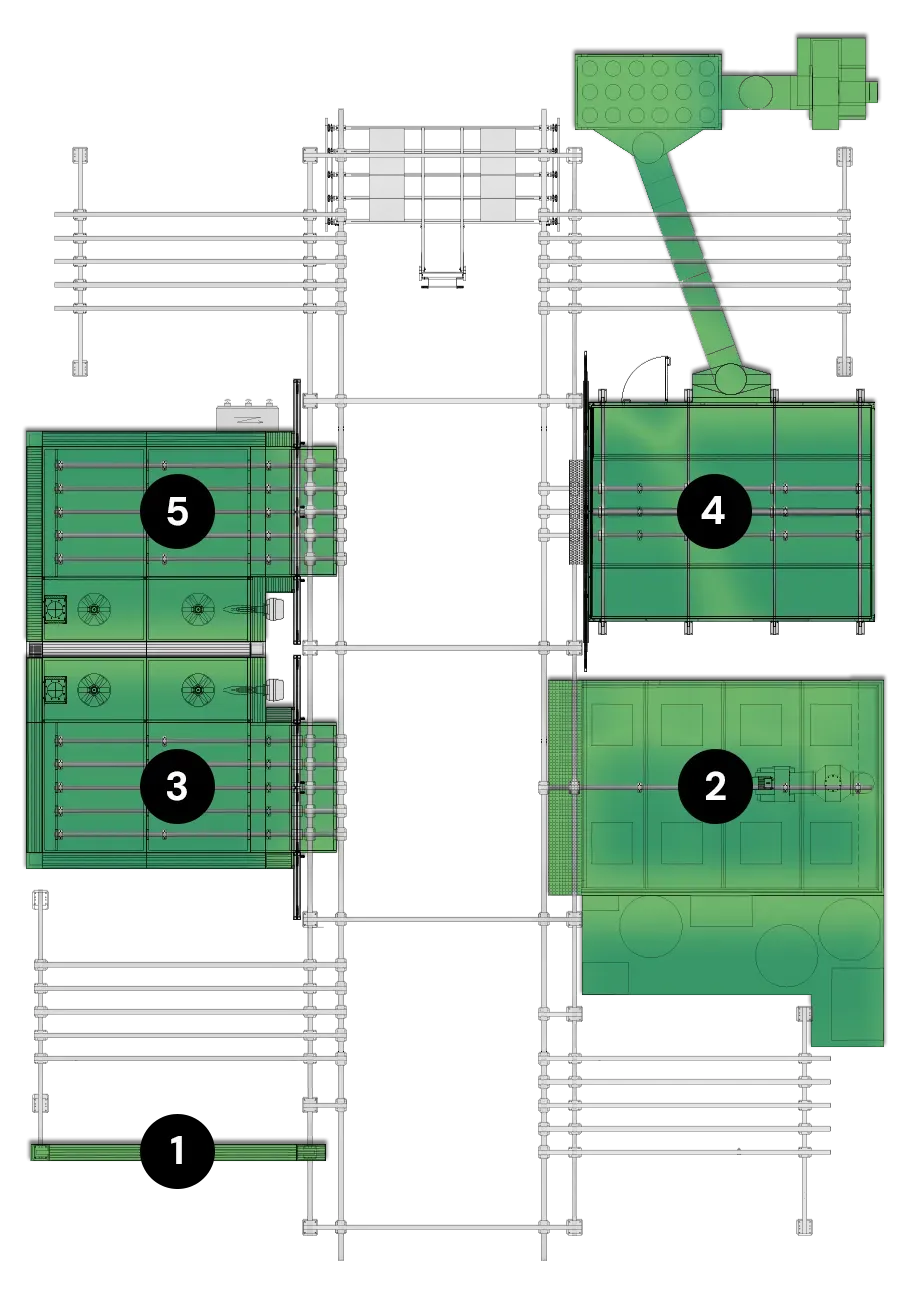

Technical Specifications:

- Max Product Dimensions:

L 4500 x H 2000 x W 1200 mm

- Max Product Weight: 250 kg per hanger beam

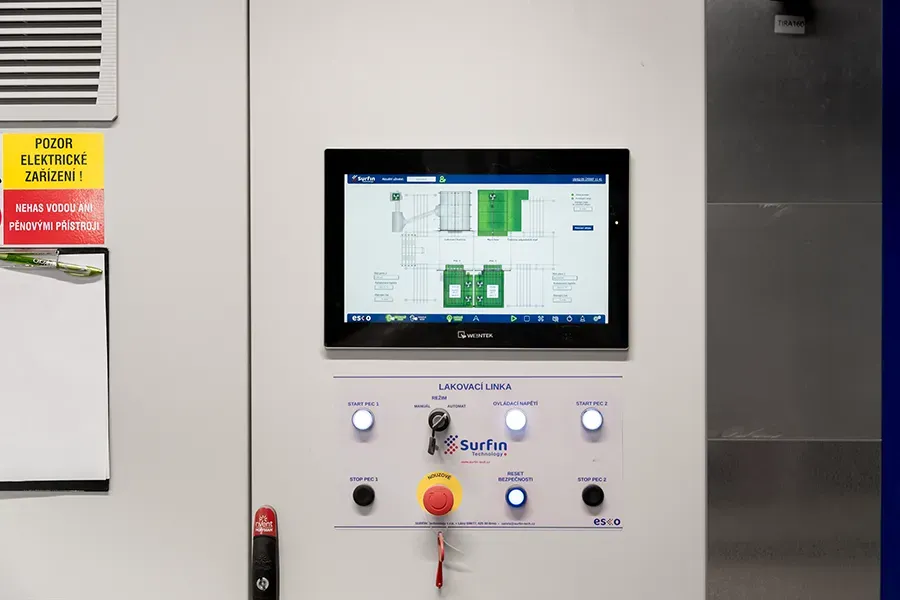

- ESCO control system

- Manual conveyor

- Floor-type powder coating booth

- Nordson Encore LT manual powder spray system

- Drying oven

- Curing oven

- Wash booth

- Max Product Dimensions:

-

Client:mmcité, a.s.

-

Year of Implementation:2024

-

Location:Veselí nad Moravou (CZ)

-

Technical Specifications:

- Max Product Dimensions:

L 4500 x H 2000 x W 1200 mm

- Max Product Weight:

250 kg per hanger beam - ESCO control system

- Manual conveyor

- Floor-type powder coating booth

- Nordson Encore LT manual powder spray system

- Drying oven

- Curing oven

- Wash booth

- Max Product Dimensions:

Technical Description of the Implementation

New Manual Powder Coating Line Helps mmcité Meet Growing Production Demands

Simplified Handling for a Diverse Product Range

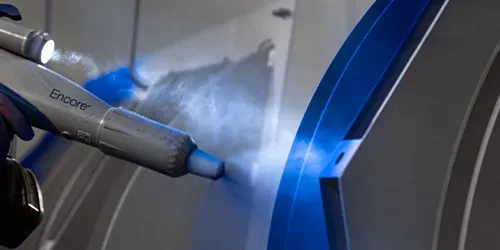

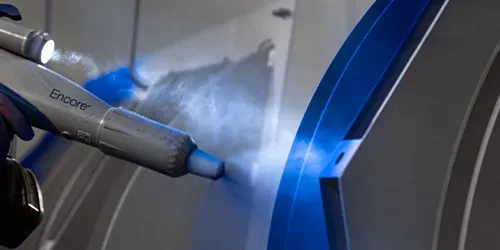

Efficient Manual Powder Coating

Smart Control System Integration for Full Process Oversight

Let’s take a detailed look at the coating process.

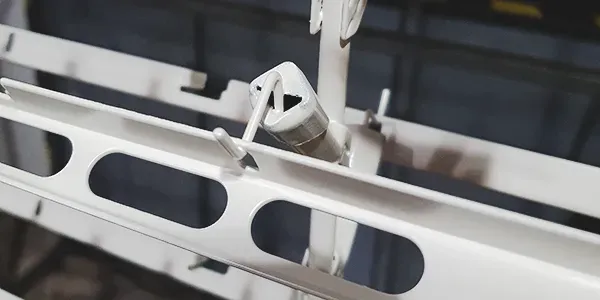

Efficient Part Hanging

The loading station at mmcité allows multiple parts to be hung simultaneously, helping increase the overall capacity of the line. The hanger beam can be easily lowered for convenient loading of larger and heavier parts.

Once the parts are hung, the entire beam can be manually moved onto the overhead conveyor.

Surface Cleaning for Flawless Finish Quality

For all parts entering the powder coating line, it is crucial to ensure a clean surface before coating.

The manual washing booth enables fast and effective spraying that reliably removes dust and other surface contaminants.

Drying Parts Before Coating

After washing, each part must be thoroughly dried — residual moisture on the surface can lead to defects in the final powder-coated finish.

A short stop in the drying oven removes any remaining moisture and prepares the product for coating.

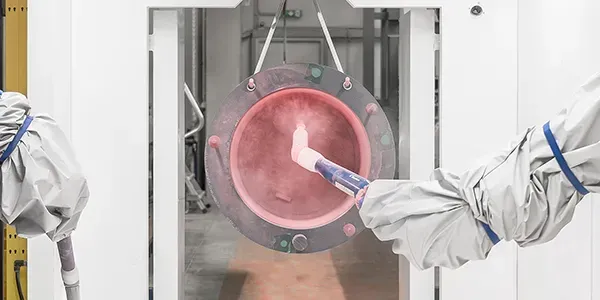

Manual Powder Coating of Components

Final Powder Curing

Efficient Part Hanging

The loading station at mmcité allows multiple parts to be hung simultaneously, helping increase the overall capacity of the line. The hanger beam can be easily lowered for convenient loading of larger and heavier parts.

Once the parts are hung, the entire beam can be manually moved onto the overhead conveyor.

Surface Cleaning for Flawless Finish Quality

For all parts entering the powder coating line, it is crucial to ensure a clean surface before coating.

The manual washing booth enables fast and effective spraying that reliably removes dust and other surface contaminants.

Drying Parts Before Coating

After washing, each part must be thoroughly dried — residual moisture on the surface can lead to defects in the final powder-coated finish.

A short stop in the drying oven removes any remaining moisture and prepares the product for coating.

Manual Powder Coating of Components