Robotic coating unit for powder coating of fuel dispensers

-

Client:TATSUNO EUROPE a.s.

-

Year of implementation:2025

-

Location:Blansko (CZ)

-

Technical specifications:

- Max Product Dimensions:

L 2000 x H 1400 x W 600 mm

- Max Product Weight: 50 kg

- ABB GoFa collaborative robot

- ESCO Paint App for intuitive robot trajectory creation

- Nordson Encore HD powder coating application

- ESCO control system

- Coatmaster Flex

- Filtration booth

- Manual conveyor

- Gas curing oven

- Max Product Dimensions:

-

Client:TATSUNO EUROPE a.s.

-

Year of implementation:2025

-

Location:Blansko (CZ)

-

Technical specifications:

- Max Product Dimensions:

L 2000 x H 1400 x W 600 mm

- Max Product Weight: 50 kg

- ABB GoFa collaborative robot

- ESCO Paint App for intuitive robot trajectory creation

- Nordson Encore HD powder coating application

- ESCO control system

- Coatmaster Flex

- Filtration booth

- Manual conveyor

- Gas curing oven

- Max Product Dimensions:

Technical Description of the Implementation

Robotic coating unit for powder coating increases production capacity at fuel dispenser manufacturer

For our long-standing partner TATSUNO EUROPE a.s., we delivered a standard robotic coating unit for powder coating. Replacing the original coating procedures, the new robotic solution provides operators with an advanced tool that simplifies work while increasing both capacity and efficiency across the entire coating process. The unit integrates our ESCO Paint App, allowing simple and intuitive robot trajectory teaching by hand. Not only does the app make operator training fast – more importantly, it eliminates the need for programming knowledge. The entire solution is designed for industrial operation and fully complies with ATEX certification for explosive environments. What other benefits does the unit provide?

Easy robot trajectory teaching with ESCO Paint App

The ESCO Paint App allows operators to create robot trajectories quickly and easily, without programming. In practice, this means any coating operator can set up a trajectory simply by guiding the robot by hand. The motion is recorded, and the software automatically generates a repeatable program. The system supports two teaching modes: in Point-to-Point mode, the operator defines individual points for smooth movement between positions, while Continuous mode precisely replicates manual motion. Program management and trajectory adjustments are fully integrated into the robot’s touchscreen panel, enabling quick and efficient reconfiguration between jobs.

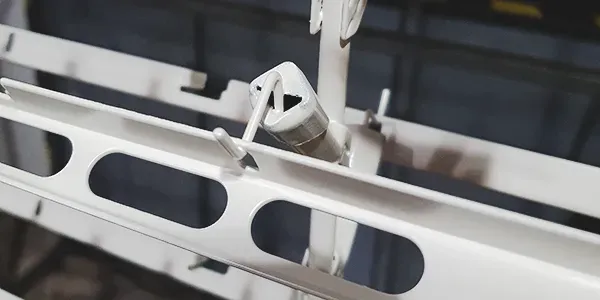

Long robot reach enables coating of multiple parts at once

The ABB GoFa collaborative robot is ideally suited for industrial coating. With an arm reach of up to 1,620 mm and a maximum coating zone of 2,000 × 1,400 × 600 mm (L × H × W), it provides excellent flexibility and can reliably coat several parts on a single hanger beam. For complete coverage from all sides, parts do not need to be removed from the unit or rotated manually. Instead, an automatic turning station with precise positioning rotates the parts once one side is coated, and the program then applies coating to the opposite side. This ensures a stable process with high repeatability.

High-speed powder coating with 0.02 mm accuracy

The unit achieves coating performance of up to 3 m² per minute. During application, the robot moves at speeds of up to 600 mm/s, while transitions between coating positions are carried out at up to 2,000 mm/s. This significantly reduces the overall cycle time. With positioning accuracy of up to 0.02 mm, defects are minimised, interventions in the process are reduced, and consistently high surface quality is maintained even under heavy production loads.

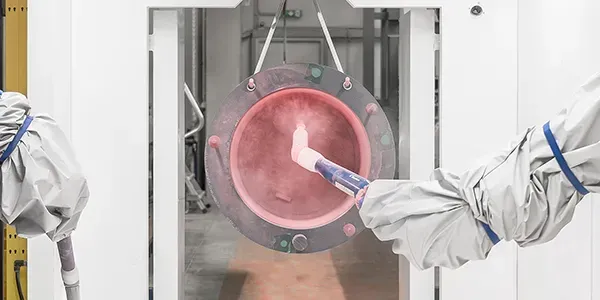

Stable powder application with Nordson HDLV technology

The Nordson Encore HD applicator with HDLV technology ensures stable powder coatings application with up to 30% lower powder consumption compared to Venturi systems. The durable pump design reduces the need for servicing, while the optimised powder feed to the gun allows the robot to reliably coat even hard-to-reach areas. The result is a consistent layer without the need for additional overspray. To enhance quality control at the customer’s request, the unit was equipped with the optional Coatmaster Flex measuring device, which enables fast, contactless measurement of uncured powder coating thickness.

Safe, flexible and compact coating operation

The integrated safety system with scanners continuously monitors the working zone and immediately stops the coating process if the zone is breached. Thanks to sensor integration, there is no need to fence off the unit, which increases placement flexibility and reduces floor space requirements. Despite this, the unit is fully compliant with the highest safety standards. To ensure durability, the robot is also fitted with a protective sleeve, which extends its service life in dusty environments and contributes to long-term performance stability.

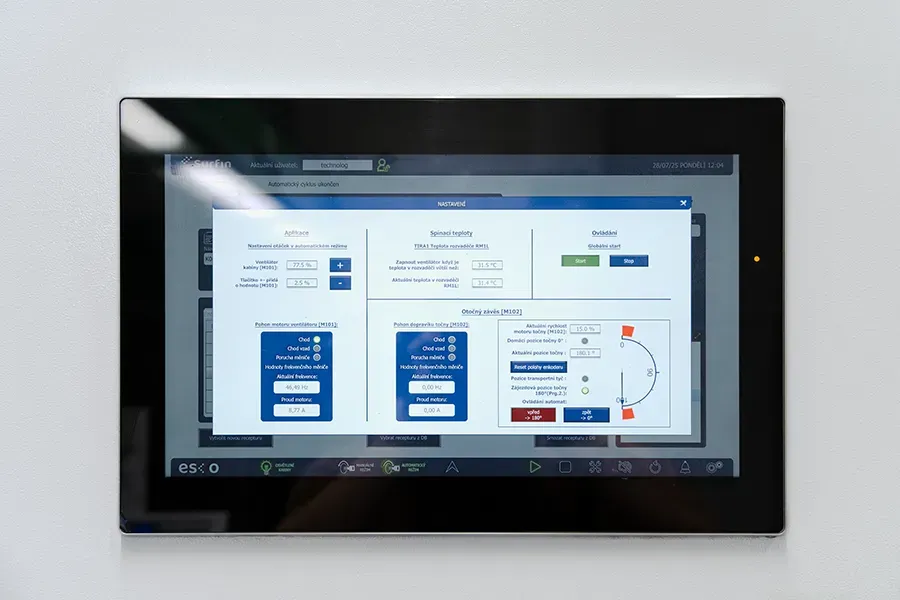

Industry 4.0 digitalisation in coating operations

The robotic coating unit brings Industry 4.0 standards into daily production. The ESCO control system consolidates program data, trajectories, and coating parameters into the main touchscreen panel. Operators can quickly set coating speed, powder flow, voltage, recipes, and safety parameters, while monitoring results and repeating proven processes consistently across shifts.